|

Motor Oil

In engines, there is inevitably some exposure of the oil to products of internal combustion, and microscopic coke particles from black soot accumulate in the oil during operation. Also the rubbing of metal engine parts inevitably produces some microscopic metallic particles from the wearing of the surfaces. Such particles could circulate in the oil and grind against the part surfaces causing wear. The oil filter removes many of the particles and sludge, but eventually the oil filter can become clogged, if used for extremely long periods. The motor oil and especially the additives also undergo thermal and mechanical degradation. For these reasons, the oil and the oil filter need to be periodically replaced.

The vehicle manufacturer may specify which SAE viscosity grade of oil should be used for the vehicles it produces, but many different weights can actually be used. Some manufacturers have specific quality test requirements or "specs" for service in their particular make. In the USA, most quick oil change shops recommended intervals of 5,000 km (3,000 mi) or every 3 months which is not necessary according to new car manuals from manufacturers. This has led to a 3,000 mile myth among most Americans.

Fuel Filter

A fuel filter is a filter in the fuel line that screens out dirt and rust particles from the fuel. They are normally made into cartridges containing a filter paper. They are found in most internal combustion engines.

Fuel filters serve a vital function in today's modern, tight-tolerance engine fuel systems. Unfiltered fuel may contain several kinds of contamination, for example paint chips and dirt that has been knocked into the tank while filling, or rust caused by moisture in a steel tank. If these substances are not removed before the fuel enters the system, they will cause rapid wear and failure of the fuel pump and injectors, due to the abrasive action of the particles on the high-precision components used in modern injection systems. Fuel filters also improve performance, as the fewer contaminants present in the fuel, the more efficiently it can be burnt.

Fuel filters need to be maintained at regular intervals. This is usually a case of simply disconnecting the filter from the fuel line and replacing it with a new one, although some specially designed filters can be cleaned and reused many times. If a filter is not replaced regularly it may become clogged with contaminants and cause a restriction in the fuel flow, causing an appreciable drop in engine performance as the engine struggles to draw enough fuel to continue running normally.

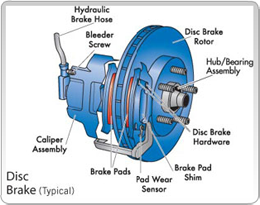

Brake pads

Brake pads are a component of disk brakes used in automotive and other applications. Brake pads are steel backing plates with friction material bound to the surface that faces the disk brake rotor.

Brake pads convert the kinetic energy of the car to thermal energy by friction. Two brake pads are contained in the caliper with their friction surfaces facing the rotor. When the brakes are hydraulically applied, the caliper clamps or squeezes the two pads together into the spinning rotor to slow/stop the vehicle. When a brake pad is heated by contact with a rotor, it transfers small amounts of friction material to the disc, turning it dull gray. The brake rotor and disc (both now with friction material), then "stick" to each other, providing the friction that stops the vehicle.

In disc brake applications, there are usually two brake pads per disc rotor, held in place and actuated by a caliper affixed to a wheel hub or suspension upright. Although almost all road-going vehicles have only two brake pads per caliper, racing calipers utilize up to six pads, with varying frictional properties in a staggered pattern for optimum performance. Depending on the properties of the material, disc wear rates may vary. The brake pads must usually be replaced regularly (depending on pad material), and most are equipped with a method of alerting the driver when this needs to take place. Some have a thin piece of soft metal that causes the brakes to squeal when the pads are too thin, while others have a soft metal tab embedded in the pad material that closes an electric circuit and lights a warning light when the brake pad gets thin. More expensive cars may use an electronic sensor.

Brake Fluid

Brake fluid is a type of hydraulic fluid used in hydraulic brake applications in motorcycles, automobiles, light trucks, and some advanced bicycles. It is used to transfer force under pressure from where it is created through hydraulic lines to the braking mechanism near the wheels. It works because liquids are not appreciably compressible - in their natural state the component molecules don't have internal voids and the molecules pack together well, so bulk forces are directly transferred to trying to compress the fluid's chemical bonds.

Hydraulic fluids

Hydraulic fluids, also called hydraulic liquids, are the medium by which power is transferred in hydraulic machinery. Common hydraulic fluids are based on mineral oil or water. Examples of equipment that might use hydraulic fluids include excavators, brakes, power steering systems, transmissions, backhoes, garbage trucks, aircraft flight control systems and industrial machinery.

Spark Plug

A spark plug is an electrical device that fits into the cylinder head of some internal combustion engines and ignites compressed fuels such as, aerosol gasoline, Ethanol, and Liquefied petroleum gas by means of an electric spark. Spark plugs have an insulated center electrode which is connected by a heavily insulated wire to an ignition coil or magneto circuit on the outside, forming, with a grounded terminal on the base of the plug, a spark gap inside the cylinder.

Timing Belt

A timing belt, timing chain or cam belt is a part of an internal combustion engine that controls the timing of the engine's valves. Some engines, like the flat-4 engine used in the VW Beetle, use timing gears. The term "timing belt" is also used for the more general case of any flat belt with integral teeth. Such belts are used for power transmission or to interchange rotary motion and linear motion, where either high loads or maintaining a specific drive ratio are important. A common non-automotive application is in linear positioning systems. Such belts have also been used in efforts to make a cleaner, lower-maintenance bicycle transmission, but have never become popular in this application.

ABS

An anti-lock braking system, or ABS (from the German, Antiblockiersystem) is a safety system which prevents the wheels on a motor vehicle from locking while braking.

A rotating road wheel allows the driver to maintain steering control under heavy braking by preventing a skid and allowing the wheel to continue interacting tractively with the road surface as directed by driver steering inputs. While ABS offers improved vehicle control, and may decrease stopping distances on dry and especially slippery surfaces, it can also increase braking distance on loose surfaces such snow and gravel. ABS has also been claimed to create a false sense of security in some drivers, who may drive more aggressively as a result, but a reduced level of braking in some other drivers when they feel the ABS pulsating.

Since initial widespread use in production cars, anti-lock braking systems have evolved considerably. Recent versions not only prevent wheel lock under braking, but also electronically control the front-to-rear brake bias. This function, depending on its specific capabilities and implementation, is known as electronic brakeforce distribution (EBD), traction control system, emergency brake assist, or electronic stability control.

|